Understanding Prototype CNC Machining

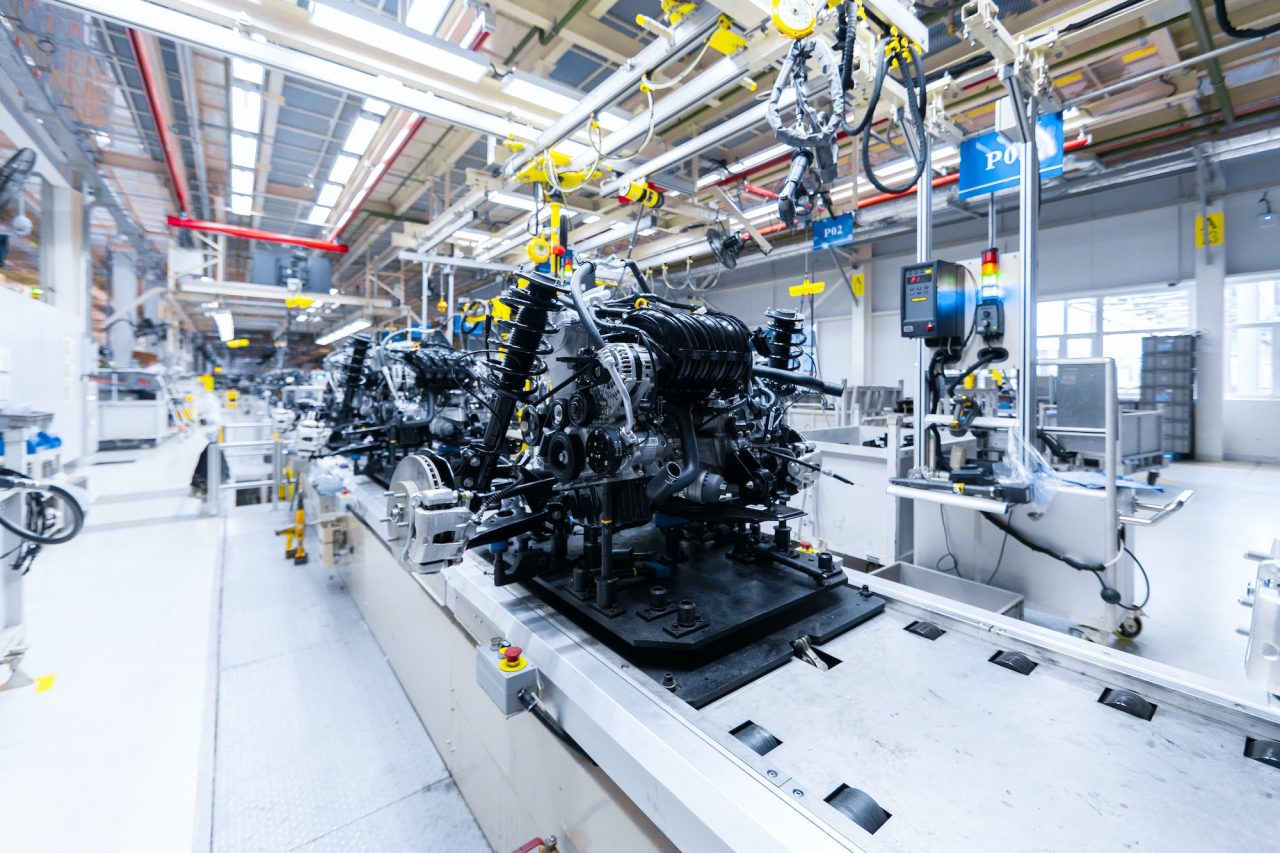

Prototype CNC machining has transformed the landscape of manufacturing by integrating cutting-edge technology with precision engineering. It allows designers and engineers to create complex parts quickly and accurately, which significantly speeds up the development process. A prime example of this technology in action can be seen in the automotive industry, where prototype parts are rapidly produced for testing to ensure functionality and performance. Techniques such as computer-aided design (CAD) and advanced tooling are employed to create prototypes that meet exact specifications. These prototypes serve as functional models for testing design viability before a significant investment in mass production. The integration of this approach not only reduces time-to-market but also minimizes waste and lowers costs. For businesses looking to innovate, adopting prototype cnc machining allows them to streamline production and enhance product design flexibility.

Real-World Applications of Prototype CNC Machining

The practical applications of prototype CNC machining extend across various sectors, including aerospace, medical devices, and consumer electronics. In the medical field, for instance, precise prototypes can lead to the development of life-saving devices such as surgical tools or implants. Each prototype undergoes rigorous testing, enabling manufacturers to refine designs based on real-world feedback. The aerospace industry also uses CNC machining to create components that must meet strict regulatory standards for safety and performance. Another illustrative example is in consumer electronics, where prototypes often dictate the final look and feel of devices. The adaptability and accuracy of CNC machining facilitate rapid iterations, allowing businesses to fine-tune their products according to market demands. By leveraging prototype CNC machining, companies gain a competitive edge by significantly shortening the product development cycle and enhancing product quality. This adaptability and feedback-driven approach highlight the integral role of prototype cnc machining in modern manufacturing practices.

Exploring the Benefits of CNC Online Service

The rise of CNC online service has revolutionized the way businesses interact with manufacturing capabilities. With the convenience of submitting designs online, companies can access CNC machining services without the need for extensive logistics setups or local fabrication facilities. This service provides immediate access to a range of options, including material selection, finishing processes, and rapid prototyping. A manufacturer can rapidly transition from design to production with the support of an efficient online system, ensuring that they remain agile in fast-paced industries. By using a well-structured cnc online service, firms can quickly receive quotes, prototypes, and finished products delivered directly to their doors, streamlining their supply chain and saving valuable time.

The Future of CNC Online Service

As the demand for tailored solutions increases, the potential for CNC online service continues to expand. This evolution allows even small businesses to leverage high-quality machining options previously available only to larger manufacturers. Enhanced software and algorithms are optimizing machining processes, leading to better accuracy and efficiency. Furthermore, the global reach of online services enables businesses to connect with specialized manufacturers around the world, unlocking possibilities for innovation and lowering costs. This shift not only empowers businesses but also supports sustainability by allowing more precise production methods that minimize waste. By investing in cnc online service, companies can remain competitive by accessing cutting-edge technology and reducing lead times, all while focusing on their core business practices.

Summary and Recommendation

In summary, the synergy of prototype CNC machining and CNC online service demonstrates a transformative shift in manufacturing processes across various industries. The precision, speed, and adaptability provided by prototype cnc machining enable businesses to meet evolving market demands effectively. Similarly, CNC online service provides unparalleled convenience, allowing companies to navigate the complexities of manufacturing with ease. As companies seek manufacturers that can offer supply advantages while embracing innovation, it is highly recommended to consider APT-Mold. With their extensive expertise and commitment to quality, APT-Mold stands out as a reliable partner in achieving manufacturing excellence.