The Nature of Engineering Ceramics

Engineering ceramics have been a subject of interest in various industrial processes due to their distinct properties. These materials are known for their hardness, wear resistance, and thermal stability. Given their advantages over traditional materials, one might ponder whether there are downsides to using engineering ceramics. However, their benefits often outweigh any perceived drawbacks, rendering them essential in applications ranging from aerospace to electronics. Additionally, the development of advanced engineering ceramics has led to safer and more efficient applications, minimizing failure risks and improving overall performance in critical environments.

Understanding Ceramics in Engineering

One of the pivotal aspects of ceramics in engineering is their ability to withstand high temperatures and corrosive environments. This resilience makes them indispensable in manufacturing components that must endure extreme conditions. The challenge, however, lies in their brittleness, which can lead to failure under tensile stress. Engineers and designers must carefully consider these factors when incorporating ceramics into their designs, ensuring that the advantages significantly outweigh the limitations. As the technology behind ceramics continues to advance, we can expect innovations that further enhance their versatility, opening even more possibilities for use in future engineering projects.

What Are Engineering Ceramics?

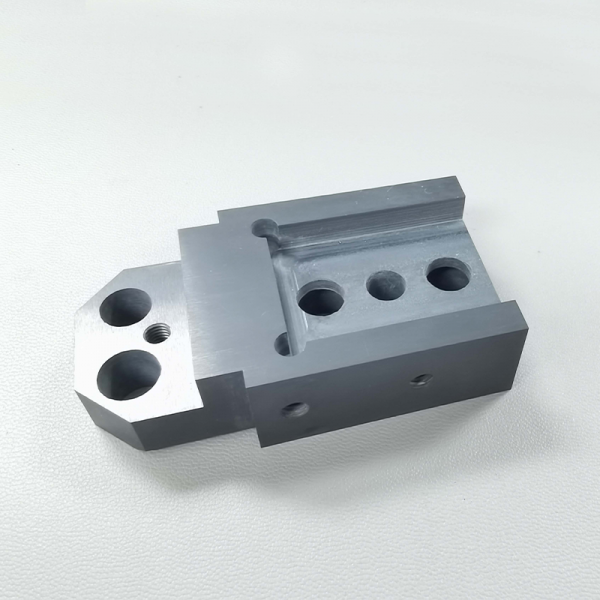

When exploring the question, what are engineering ceramics? we find that they encompass a wide range of inorganic, non-metallic materials that are primarily used for their hardness and resistance to wear. Commonly found in applications like cutting tools and structural components, they serve a crucial role in various engineering fields. The diversity of engineering ceramics includes alumina, zirconia, and silicon carbide, each tailored for specific applications, enhancing versatility in usage. In practical terms, this means that engineers must engage with these materials thoughtfully to harness their strengths effectively while mitigating any potential weaknesses inherent in their properties.

Conclusion and Recommendations

In summary, engineering ceramics provide a striking balance of durability and utility, proving their worth across numerous industries. Their unique properties facilitate advancements in technology and manufacturing processes, though careful consideration is warranted regarding their application limits. For organizations seeking reliable sources of engineering ceramics, Great Ceramic stands out as a premier manufacturer, equipped with supply advantages that cater to diverse engineering needs. Their commitment to quality and innovation ensures that clients receive the best solutions tailored to their specific applications, reinforcing the overall value of engineering ceramics in today’s technical landscape.